Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

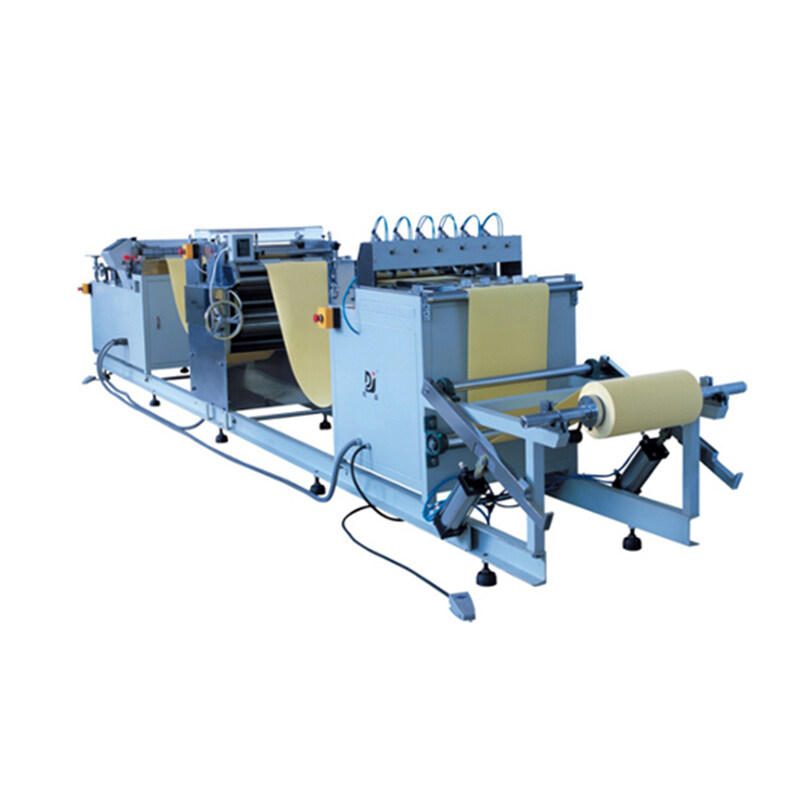

SEGT-600 Full-auto Rotary Pleating Production Line

The SEGT-600 full-auto rotary pleating production line is a fully automatic machine designed for heavy-duty air and oil filter pleating. It can produce various filter paper pleats by manual operation or PLC program, and is suitable for both domestic and industrial use.

-

Product Details

Product Introduction

The SEGT-600 full-auto rotary pleating production line is controlled by a computer program, making it easy to operate. It can produce different specifications commonly used for domestic and industrial use, and is especially suitable for making high-performance anti-fatigue pleated filter media from ordinary paper, polyester material, non-woven fabric, and waste cotton. The machine is equipped with a pre-slitter, auto-counter, heating device, and conveyor, and the process of the machine is automatic counting, pleating, preheating, and forming.

Specification

1.Pleating speed: 0-30m/min

2.Max pleating width: 600mm

3.Min pleating width: 30mm

4.Max pleating height: 50mm

5.Min pleating height: 10mm

6.The roller sizes can be customized

7.Heating power: 6Kw

8.Temperature control: normal-300 degree

9.Total power of the line: 7.5Kw

10.Air pressure: 0.6Mpa

11.Power supply: 380V/50Hz

12.Machine weight: 1100kg

13.Machine size: 6000mm*1100mm*1200mm (L*W*H)

Features of Full-auto Rotary Pleating Production Line

1.Using pneumatic slitting blades, which are highly efficient and precise. The blades are simple for regulation and evenly pressed, ensuring that the filter paper is cut accurately and uniformly.

2.Equipped with six sets of rolls on the same round table, which can be easily changed and adjusted to produce different specifications of pleated filter paper. This feature makes the machine highly versatile and adaptable to different production needs. The rolls are also suitable for producing heavy-duty air filter elements, and can be embossed on the paper to enhance the filter’s performance.

3.Designed to be easy to operate through computer control. The machine is equipped with a user-friendly interface that allows operators to easily input and adjust the production parameters. The computer program automatically controls the tension roller, round table, feeder, and shaping roller, ensuring high precision and great quality.

Advantages of Full-auto Rotary Pleating Production Line

1.Durability and Reliability:

The SEGT-600 full-auto rotary pleating production line is specifically designed for heavy-duty air and oil filter pleating, making it ideal for both domestic and industrial use. The machine is capable of producing high-quality pleated filter paper that can withstand the demands of heavy-duty applications, providing long-lasting performance and protection for the equipment it is used in.

2.Flexibility and Efficiency:

The SEGT-600 full-auto rotary pleating production line is equipped with six sets of round table rollers that can be easily replaced, making it highly convenient to choose different specifications of pleated filter paper. This feature allows for greater flexibility in production, enabling the machine to adapt to different customer needs and requirements. The rollers are also designed to be highly durable and long-lasting, ensuring that the machine can operate efficiently for extended periods of time.

3.Enhanced Performance:

The SEGT-600 full-auto rotary pleating production line can emboss the filter paper, especially for heavy-duty air filters. This feature enhances the performance of the filter paper by increasing its surface area, allowing it to capture more contaminants and particles. The embossing process is highly precise and uniform, ensuring that the filter paper is of the highest quality and performance.

4.Quality and Consistency:

The SEGT-600 full-auto rotary pleating production line features a stainless steel conveying unit that ensures the filter paper is pleated more evenly and smoothly. This feature eliminates the need for further processing or performance quality issues, ensuring that the pleated filter paper is of the highest quality and performance. The stainless steel conveying unit is also highly durable and long-lasting, ensuring that the machine can operate efficiently for extended periods of time.

FAQ

Q1:What are the company's main products?

A:The company mainly produces filter equipment, filter accessories and molds,optical screening machine.

Q2:What are the main advantages of the company's equipment?

A:Independent research and development, independent intellectual property rights, customized according to customer needs, affordable price, fast delivery.

Q3:Where can I see a video of the machine in action?

A:The operation video of our machine can be found on YouTube, FACEBOOK and other social media.

Q4: What is the ordering process for equipment?

A:Provide product drawings or photos, list specific size ranges or requirements, and we recommend the most suitable equipment.

Q5:What should I do if the device does not operate after receiving it?

A:We will provide the operation video of the machine, from the first step to all steps of normal production.

Q6:After-sales service and spare parts of the machine?A:We will provide vulnerable spare parts and supporting toolbox at random. If there is a problem in the actual use process, you can take a video of the problem and contact our 24-hour customer service at any time.